Our design process

Lamp working is a skilled process that requires not only a steady hand and an eye for detail but also months of training to master.

From Italian Murano to German Reichenbach, Pandora uses only glass of the highest quality for our charms, designed with vibrant colors and crafted by hand.

Our high recycling rate is driven by 100% recycling rates for, e.g. glass, which is recycled into various glass products.

Each Pandora glass charm is unique and may contain small variations in design, color and size. Some charms may even contain small glass bubbles, which is not a mistake.

It takes months of training to create a simple glass charm and up to one year to be able to make one of Pandora’s more complex designs.

Murano is and has always been renowned for producing high-quality glass noted for its colors and innovative new techniques.

Some of our jewelry designs feature a combination of Italian Murano glass and German Reichenbach glass.

Lamp working is a skilled process that requires not only a steady hand and an eye for detail but also months of training to master.

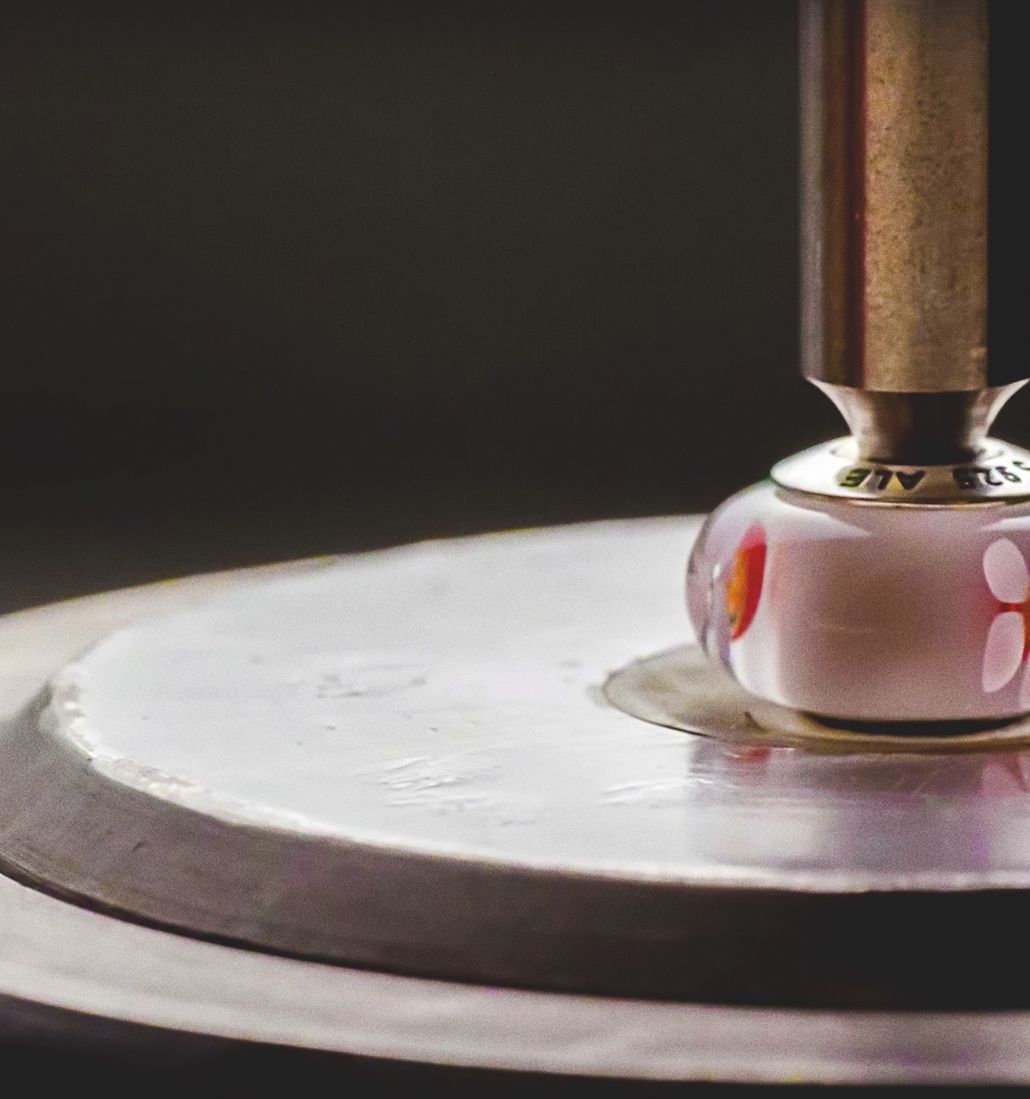

Glass rods are heated over flames until they become molten glass. Then, it's wound around a coated steel mandrel. The process forms the base charm, which can then be decorated using a variety of techniques.

The next step is the annealing process. The glass is heated and cooled in an alternating process to ensure durability and to prevent the glass from developing stress points. It's important to avoid these as they could later cause the glass to crack or shatter.

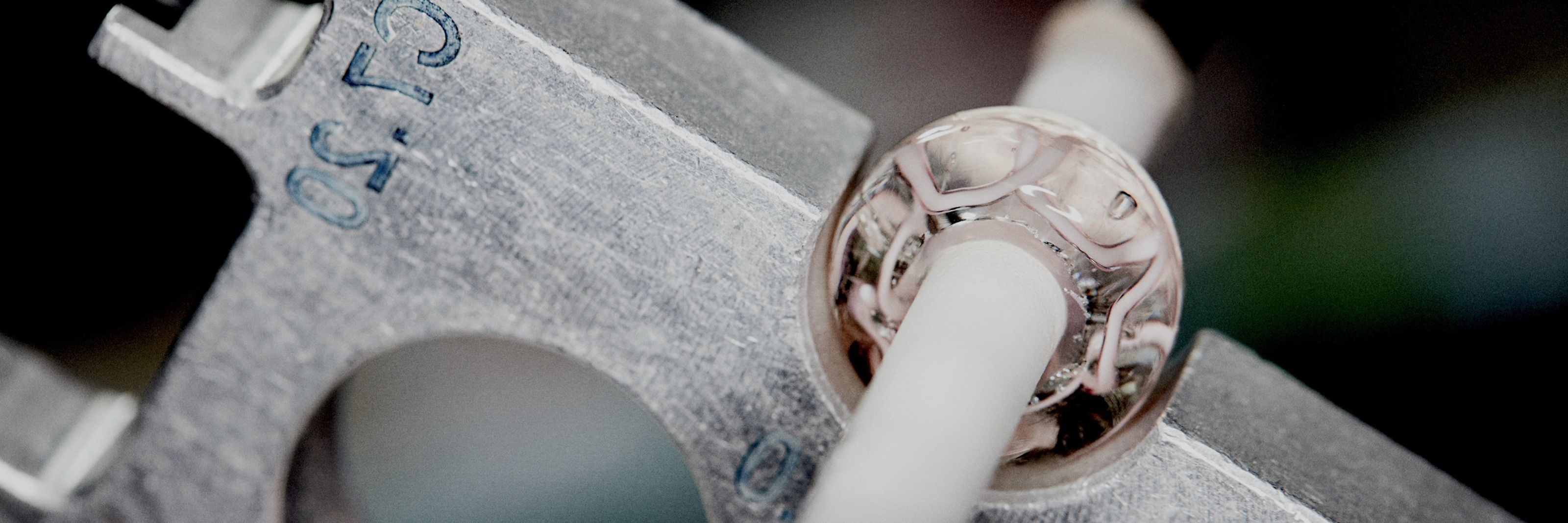

Finally, the glass charm is fitted with a hand finished metal core, ready for wear on bracelets.

The first look is called murrine. It's made by hand and requires a high level of scale and a great deal of patience. The possibilities are endless and range from naïve shapes to highly detailed portraits.

A pattern reminiscent of marble creates an intriguing effect on glass charms. First, the colored base is made by melting a glass rod and wrapping it around a steel rod. Next, the resulting bead is rolled in golden-colored frit: small pieces of granulated glass. The charm is then heated again, melting the frit which spreads across the surface to create a marbled effect. A layer of clear glass is then added and a steel-tipped tool is pressed quickly into the molten glass to introduce air that creates a series of bubbles. A final layer of clear glass completes the charm, which is then cooled before being fitted with a metal core.

Our nature-inspired glass designs are beautiful examples of glass craftsmanship at its best. Featuring pretty floral motifs or butterflies within the glass, each piece is created by hand using a process that requires many different steps and colors. A base layer of glass is created, onto which dots or lines are added using glass stringers – ultra thin glass rods. Using a special tool, the stringer shapes are drawn into miniature motifs. A final layer of transparent glass is then applied on top, refracting the pattern through it. A three-dimensional effect can also be achieved by inserting a pointed tool into the pattern and through to the glass layer beneath. This is how the stems of flowers are created.

Showcasing pretty hearts that appear to float within the charm, the effect is achieved with slender glass stringers in tonal pink hues that form the shapes on a clear glass base. The inner layer of glass also contains dichroic glass which displays two different colors to give the charm its unique iridescent effect. The piece is finally encased in a layer of clear glass. No two designs are exactly the same.

Faceted Murano glass charms are shaped from a large base, as parts of it will be cut away during the faceting process. Once the base charm has cooled and annealed, it is shaped with a faceting machine that cuts a total of 70 facets. When the light hits the delicately crafted design, the facets reflect it beautifully.

Glass beads are given surface texture while still warm, by rolling them on a grooved mold to create intriguing ripples reminiscent of shapes found in nature.

A base design is set evenly with round brilliant-cut cubic zirconia stones in the molten glass. Next, a pointed tool is inserted into the core layer to make delicate air bubbles before the bead design is sealed with a final layer of translucent glass.

Some of our innovative glass designs combine dichroic and fluorescent glass to create a fairy-tale feel that represents the signature color of Disney’s much-loved characters. Dichroic glass – essentially two-tone glass – brings an enchanting, colour-changing effect to charms depending on the viewing angle. Fluorescent glass adds a subtle glow-in-the-dark effect.

Heart-shaped cubic zirconia stones are embedded individually in the glass by hand on this challenging design. Each stone is spaced evenly, facing the same direction, in a painstaking process that requires exceptional hand-eye coordination.

A soft iridescent effect is achieved through the use of dichroic glass. Dichroic, or two-colored, glass displays two distinctive colors when viewed from different angles. A highly specialized product, dichroic glass is created by fusing thin layers of glass together with metallic oxides. The process is undertaken in a vacuum chamber using a high-voltage electron beam.

There are many quality control checkpoints during our crafting process, the timing of which varies from one crafting facility to another. This tends to be where our first check takes place.

Meet our first-ever square Murano glass charm. Our pioneering approach to craftsmanship turned the challenge of creating his eyes and mouth into the opportunity to handcraft distinguishing features. Each expression is different on each charm, and so perfectly unique to you.

Glass charms with variations of bubbles are not faults in the product, but rather an evidence of the high degree of craftsmanship involved in making of each glass design, and the details created by hand, which means that no two charms are exactly the same.

Pandora’s glass charms are primarily made from glass imported directly from Murano, an Italian island in the Venetian Lagoon.

Pandora’s glass charms are primarily made from glass imported directly from Murano, an Italian island in the Venetian Lagoon.

Some of our jewelry designs feature a combination of Italian Murano glass and German Reichenbach glass. It is particularly noted for its range of glass in brilliant saturated colors as well as the crystal clear quality of its transparent glass.

Glass is a natural product that can be reclaimed and recycled many times over. When a glass artisan creates a piece of jewelry, a small amount of glass is left over from production. The most recent addition to Pandora’s glass material is the Beautifully Different jewelry collection, which uses this surplus Murano glass to create unique, one-off colors and designs.

For daily cleaning of your glass jewelry, polish with a soft, lint-free cloth.

For deeper cleaning, wipe gently with a soft, lint-free cloth dampened with lukewarm water that has a small amount of liquid soap dissolved in it.

Wipe over with clean water and pat your jewelry dry with a soft cloth. For a high-shine finish, buff with a small amount of mineral oil.

Keep your Pandora collection as sparkly as you are! Discover how to clean your jewelry and give it the care it deserves.